G3: woodworking tools

and much more

The values of our company

Tradition

Worldwide vision

Technology

Customer-oriented company

Italian genius

G3 is one of the main international companies in the market of tools for working wood, its derivatives, plastic and aluminum. From our headquarters in Poggibonsi, in the heart of Tuscany and Italy, we export the quality and the genius typical of Made in Italy all over the world.

G3 high-precision tools are the result of a long experience and in-depth artisan knowledge, shaped by decades of constant innovation and application of the most modern technologies.

Thanks to the quality of our tools, and to our professional, dynamic, and transparent approach, we have world-wide customer satisfaction

Our history

Over time they have been able to make their father’s legacy their own, applying the principles of quality, seriousness and experience in an innovative and modern way. The name G3 comes from the three “G’s”, which are the initials of father and his new generation

Active since its origins in the global market of woodworking tools, our company has always stood out for the quality of the product and the widespread assistance made available to its customers.

In 2001 G3 moved to its current corporate headquarters. A perfectly organized structure that includes all the different business sectors: marketing, sales and customer assistance and service.

Here our company became what it is today: an established business in the field of tool production.

A very important step in this area was the acquisition of GI.MA. Utensili, a company specialized in the production of brazed tools: all the equipment has been transferred to our production center. At the same time, new expert technicians have joined G3, allowing us to further improve our production.

How our tools are born

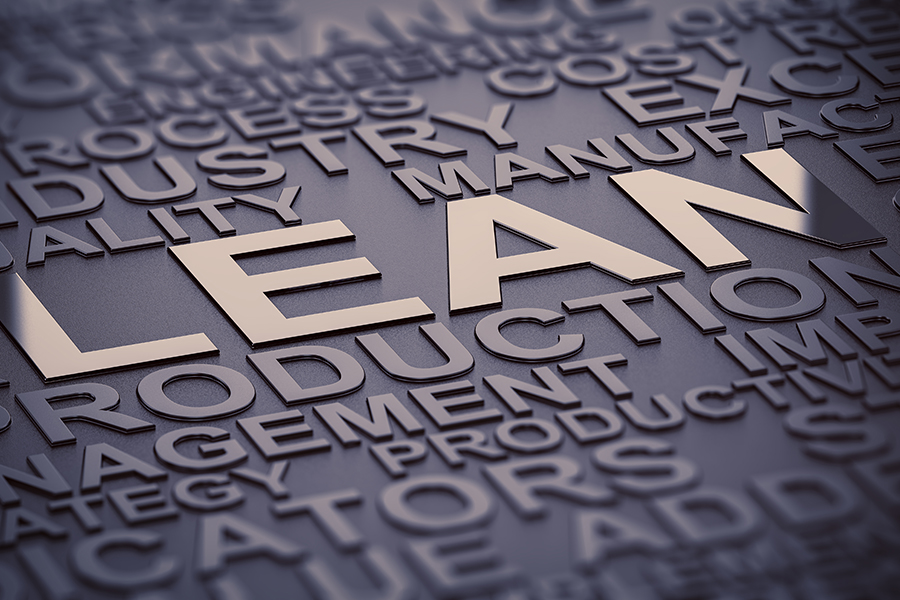

The production of our tools for working wood, its derivatives, plastic and aluminum – which include cutters, bits, heads, blades, groups for doors and windows and other accessories – is the result of the work of a close-knit team of professionals, forward-looking company policies, innovative industrial processes, a careful selection of high quality machinery and raw materials.

Skilled team

Technology

Innovation

Quality

Sustainability

Company policy

We protect the health of our workers by observing strict safety protocols and trying to make the working environment as comfortable as possible. We constantly promote initiatives aimed at increasing widespread and shared environmental responsibility within our company and our local area.

Our team works efficiently according to the principles of lean production. We pay the utmost attention to productivity in order to promptly meet the demands of our customers.

Machinery

G3’s production department is continuously updated with new machinery and equipment. This allows us to improve our production capacity and our speed in delivery times day by day.

The production process

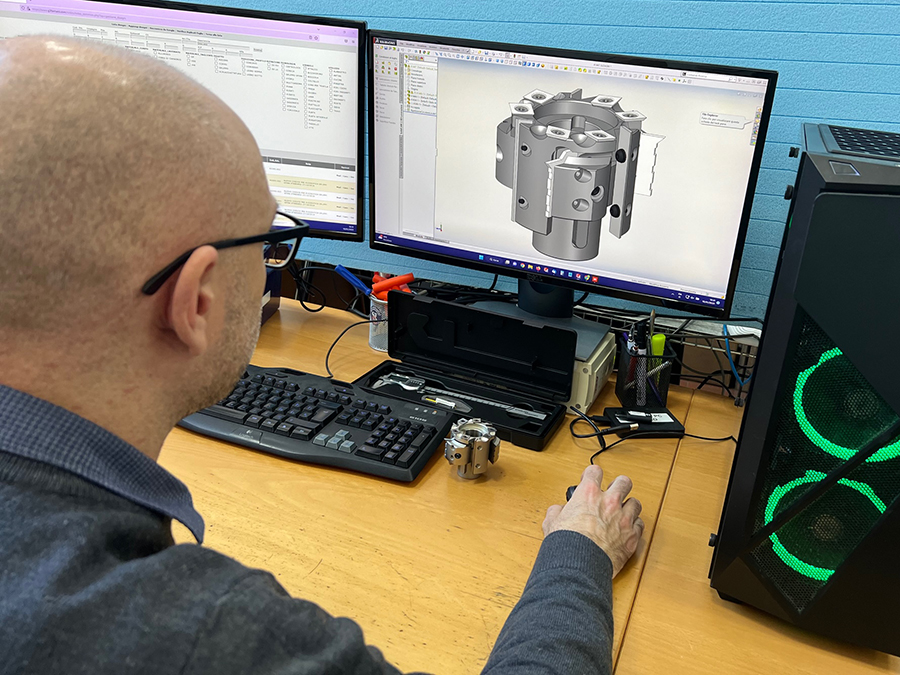

The G3 production process begins in the technical office, where all projects are carried out by a team of specialists. The design is performed by a three-dimensional CAD simulation program which, from the start, allows the team to see the final outcome of the tool.

Once the project is finished, the file is transferred directly to our machines which permit us to monitor the production process with utmost precision.

Each project is assigned a number, thanks to which we are able to understand how each individual tool was made and to obtain all the necessary information for spare parts.

The entire basic process is performed on automatic equipment and numerical control machinery, minimizing the possibility of errors and guaranteeing maximum precision. These cutting-edge machines never interrupt their processes, guaranteeing efficient and continuous work even at night and on weekends.

Each product is made with high-quality raw materials, selected over years of work and coming exclusively from the European Union, mainly from Italy and Germany.

Quality control

The same attention is paid to packaging. The packages in which the products are shipped, are prepared to prevent any type of damage during transportion.

At your side from purchase to after-sales

G3 puts a complete Customer Service, from start to finish…from the first contact until after-sales.

We are firmly convinced that full customer satisfaction is fulfilled only through continuous attention and listening skills, which we gladly make available to all our customers and partners.